A range of proximity sensors for machine/industrial control systems producents

|

|

|

Micros offers a wide range of components for automation , such as: industrial connectors, lighting, regulators and industrial computers, as well as various electronic components. Recently, cylindrical proximity and photoelectric sensors, which are really popular in the industry, had been added to the offer of the Cracovian supplier. We want to show you the offer and practical tips.

Most popular ones - inductive sensorsThese are probably the most widespread group of proximity sensors in the industry. They are used wherever there is a need for non-contact detection of metal objects. They register presence of metal in the detection zone. Inductive sensors are characterized by high operational reliability and dependability. Due to the IP67 protection, the sensors can work in harsh environmental conditions . The operating range, the so-called working zone, depends on the size of the detector element (coil) and is usually proportional to the length of the sensor. In classic designs, after demodulation, the oscillator signal is directed to the Schmitt trigger. Typically, the sensor’s output/outputs are NPN or PNP transistors. They can be configured in two ways: output transistors can be turned on when the sensor detects an object (NO - Normal Open) or when it does not detect it (NC - Normal Closed). Inductive sensors are most commonly used in oval, metal and threaded housings. The big advantage of these housings is the ease of installation Many sensors have LEDs that indicate the current state of the sensor. Besides classic sensors, producer offers models for hazardous areas, food industry, increased temperature resistance, vehicles, or ones, that are resistant to specific chemicals/pressure washers. Podstawowe parametry oferowanych przez Micros czujników indukcyjnych z serii CZ LMxx to:

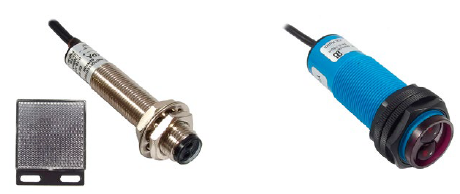

Photoelectric elements: large range and versatilityOptical (photoelectric) sensors use light radiation to detect transparent and opaque objects. They consist of a light source and a receiver (interruption of the beam triggers the sensor). These items come in several types in terms of detailed working principles like: Retroreflective- in their case, the transmitter and receiver are built into one housing, and the beam is sent by the emitter. When an object appears on its way, it will be reflected by it and returned to the detector (which is detected and signalled). The advantage of this solution is the simple installation, and the disadvantage - the relatively short range and the fact that the accuracy of operation may depend on the colour or object. Reflective - the transmitter and receiver are in one housing, the beam of rays is reflected from the reflector (located at the other end of the sensor's detection area). The object is detected when the beam does not reach the receiver. The montage is more complicated than with the previous sensor. A huge plus is the bigger range- up to several meters. These sensors are also more universal and insensitive to the colour of the detected object. Thru beam - the transmitter and receiver are separated and the light rays form a barrier between them. Capacitive versions: for material detectingIn situations where inductive sensors cannot be used (e.g. due to the need to detect non-metallic objects), capacitive sensors are usually a good alternative. They allow detect any type of materials (both metallic and non-metallic), but have a shorter range than inductive ones. The group of non-conductive includes, e.g. plastics, glass, porcelain, wood, paper, organic materials etc. Additionally, the discussed elements are sensitive to various kinds of dirt and obstacles appearing between them and the detected element. These elements are used in advanced automation as well as in simple building automation, machines and industrial applications. Work of these sensors may be difficult in a dusty environment - dust may settle on the transmitter or receiver, and interrupt the beam thus giving false positive detection. Features and parameters of the CZ Gxx photoelectric sensors offered by Micros are:

Typically, capacitive sensors are used to detect overflowing of a liquid or bulk material. They are also used, to detect various objects (e.g. transported on a belt conveyer), to measure the thickness (e.g. of wood or foil). They operate similarly to the induction models and differ only in the work principle. Instead of a coil a virtual capacitor is created form an object near the sensor and internal plat. Object type and its movement changes properties of this capacitor, which is detected by the sensor circuitry The sensors are available in various designs, adapted to specific working environments. Thanks to various types of outputs, the element can be adapted to the individual preferences. When it comes to capacitive sensor, it is worth paying attention to the maximum detection frequency of the sensor, which in fact is dozens of Hz. This reduces the use case of these elements in very fast applications in favour of a photoelectric models. Both types are resistant to dirt, but react differently to different contamination, depending on the situation, one or the other may be a better solution. Compared to, for example, inductive sensors, the advantage of capacitive sensors is their high resistance to electromagnetic interference. The parameters of the CZ CMxx series:

Hall-effect sensors- complement to the offerHal-effect devices are proximity sensors that detect the presence of permanent magnets (in the case of Micros components, the working range is 10 mm). The feature that distinguishes them from the inductive versions is the lack of reaction to metals. These types of sensors are widely used in machine construction (particularly milling machines) as well as in industrial automation and production lines. They are adapted to work in difficult conditions, where high humidity and dust may cause distortions. In addition, they are characterized by high efficiency and durability. The parameters of the CZ SMxx sensors;

SummarySensors are indispensable elements of modern machines and industrial automation systems. The article presents four groups of products realised in the Micros offer (2018). A complete description of the range of sensors can be found on the website Source: "Elektronik" 2019/02, p. 71-73. |

Examples of photoelectric sensors: CZ G12-3B1PA (reflective, range 1 meter) and CZ G30-3A70PC (reflective, range 70 cm)

Miniature capacitive sensor CZ CM12-3004NA with dimensions 12 × 58 mm and range 0 ~ 4 mm and sensor with a built-in front CZ CM30- 3010NA with a range up to 10 mm, dimensions 12 × 63 mm, range up to 4 mm)

|

|

|

|

|

|

|

|

|||