Discover the fascinating world of Hall sensors

GoChip – Expert in Hall Sensors

Founded in 2010 and headquartered in Shanghai, GoChip Microelectronics specializes in integrated circuits for sensors, particularly those based on the Hall effect. Their product range includes various types of Hall sensors, motor drivers with integrated Hall sensors, and inductive sensor controllers. The company is a dynamic manufacturer with a strong focus on the automotive sector, but also has a presence in industrial automation and consumer electronics. With over 10 years of experience in designing semiconductor solutions for automotive applications, GoChip places a strong emphasis on developing new products and technologies. The company’s motto is “Grow and Exceed Expectations,” and its strategic goal is to become one of the key semiconductor players in China.

The Hall Effect – What It Is and Why It Matters

The Hall effect is a physical phenomenon in which a voltage is generated in a current-carrying material when exposed to a magnetic field. This Hall voltage is a measurable signal proportional to the magnetic field strength. The Hall effect forms the basis of all Hall sensors used for detecting magnetic fields, position, rotational speed, or current. Its applications range widely – from tiny smartphone sensors to large systems in electric vehicles. Key advantages include:

- Contactless measurement – no mechanical wear compared to potentiometers or micro-switches.

- Resistance to dust and dirt – ideal for automotive and industrial environments.

- Miniaturization potential – easily integrated into ICs.

GoChip Microelectronics Product Overview

Hall Sensors

GH39 and GH1321 are linear (analog) Hall sensors, where the output voltage is proportional to the magnetic field strength. These sensors can detect changes in field strength continuously, allowing the measurement of not just presence, but also the strength and direction of the field. They offer high accuracy, sensitivity, and temperature stability, making them suitable for motion sensors, proximity sensors, liquid level sensors, current sensors, and motor control (rotation and position measurement).

GH43F, GH1210, and GH1248 (SOT23) / GH1248 (TO92S) are digital on/off Hall sensors that detect the presence or absence of a magnetic field. GH43F and GH1210 are unipolar (reacting only to one magnetic pole), while GH1248 is omnipolar (reacting to any pole). Unipolar sensors are ideal when detecting a specific pole is required, while omnipolar sensors are more versatile and detect the presence of a field regardless of direction. Typical applications include limit switches, door/window detectors, and simple rotation counters.

GH2101 This, in turn, is a digital on/off latch-type sensor — meaning it changes its output state when the magnetic field exceeds a specified positive threshold (Brp = 80 GS) and remains in that state until exposed to an opposite magnetic field that exceeds the negative threshold (Brp = –80 GS). The latch “remembers” that the magnet has crossed the threshold and will not change state until the opposite pole appears. Therefore, it is ideal for environments with vibration and interference, typical in automotive applications, and especially where magnetic position information is required and the signal must remain stable and unaffected by temporary field fluctuations. Typical automotive applications include: seat motor position detection, smart cockpit systems – rotation angle detection (e.g. knobs or dials), power window sensors, and sensors for sunroofs or tailgates.

It is compliant with the automotive AEC-Q100 standard.

GH1922 and GH1820 These are differential Hall sensors, meaning they integrate two Hall elements placed close to each other on a single chip. Such a configuration measures the difference between the signals from the two points instead of the absolute magnetic field. This eliminates the influence of uniform background magnetic fields, such as the Earth's magnetic field or interference from nearby components, and the system responds only to changes in the field generated by a nearby magnet. The main advantages of this solution include minimization of temperature drift effects, reduced impact of manufacturing process variations, immunity to background magnetic fields, and high accuracy and reliability. In practice, combining these features results in higher sensitivity, more consistent readings, lower noise susceptibility, and more reliable operation in harsh environments. These are smarter sensors that do not react to common-mode disturbances such as temperature changes, background fields, or production tolerances, but only to the actual signal from the magnet. The GH1922 features a single output channel, while the GH1820 has two channels.

GH1817 This is a so-called “geared Hall sensor,” a specialized variant of a Hall sensor designed to detect the movement of the teeth and gaps of a gear wheel, and thus primarily used to measure its rotational speed. This type of sensor works with a magnet placed directly behind the sensor chip and, thanks to built-in adaptive algorithms, automatically adjusts to the magnetic field range generated by that magnet. The sensor can detect the presence or absence of a tooth even when the gear is stationary (zero rpm), allowing full speed detection from zero up to very high rotational speeds. This represents a significant advantage over conventional inductive sensors, which generate a signal proportional to speed and do not operate at very low or zero speeds. Thanks to its adaptive logic, precise alignment of the sensor relative to the gear wheel is not required. In practice, this means greater installation tolerance and resistance to slight mechanical shifts during operation.

|

Symbol |

Package |

Sensor type |

Operating voltage |

Magnetic characteristics |

Operating temperature |

Possible replacement for: |

|

SOT23 |

Linear |

3~6.5V |

B = ±1000GS type |

-40~85°C |

ALLEGRO A1304 / A1326 |

|

|

TO92S |

Digital on/off, unipolar |

3.8~30V |

Bop = 70~200GS Brp = 50~170GS |

-40~150°C |

INFINEON TLE4905 |

|

|

TO92S |

Digital on/off, unipolar |

2.8~24V |

Bop = 45GS Brp = 30GS |

-40~125°C |

ALLEGRO A1230 |

|

|

SOT23 |

Digital on/off, omnipolar |

1.8~5.5V |

Bop = ±30GS Brp = ±20GS |

-40~85°C |

ALLEGRO A3211 |

|

|

TO92S |

Digital on/off, omnipolar |

1.8~5.5V |

Bop = ±30GS Brp = ±20GS |

-40~85°C |

ALLEGRO A3211 |

|

|

TO92S |

Linear |

3~7.5V |

B = ±420GS type |

-40~150°C |

ALLEGRO A1324 |

|

|

TO92S |

„Geared” |

1.8~5.5V |

Adaptive logic, Bhys = 30GS |

-40~150°C |

INFINEON TLE4922 |

|

|

TO94 |

Differential, |

3.8~30V |

Bop = 0GS Brp = 0GS |

-40~150°C |

|

|

|

TO94 |

Differential, |

3.5~24V |

Bop = 0GS Brp = 0GS |

-40~150°C |

|

|

|

TO92S |

Digital on/off (latching) |

3~24V |

Bop = 80GS Brp = -80GS |

-40~150°C |

ALLEGRO A1210 / A1212 |

Table 1. Summary of GoChip Hall Sensors

Motor drivers with built-in Hall sensor

In addition to Hall sensors alone, GoChip offers devices that combine a Hall sensor with a BLDC motor control circuit.

GH477 This is an integrated single-phase BLDC motor driver, primarily designed for fans and low-power micro-motors (12V/350mA). It combines a high-sensitivity Hall sensor, commutation logic, and a current driver capable of directly driving the winding within a single structure. The output driver operates in a full-bridge configuration, providing higher efficiency compared to simpler half-bridge topologies. The system requires a minimal number of external components, resulting in a compact PCB and a low-cost, reliable drive. It features built-in protections against reverse power connection (Reverse Power Protection, RPP) as well as thermal protection. Thanks to the integration of the Hall sensor, the GH477 is well suited for very small drive modules and applications with limited space for electronics, such as mini fans in household appliances or motors in medical devices.

GH4112 This is a device similar to the GH477, but it additionally features automatic locked rotor protection (Locked Rotor Protection, LRP) and an automatic restart function. When a BLDC motor is mechanically stopped (e.g., a fan blocked by dust, an obstacle, or a finger), the winding begins to draw very high current. This condition can cause winding overheating, damage to the current driver, and reduced system lifespan. The GH4112 detects this state and disconnects the coil power, protecting both the driver and the motor. The device does not remain permanently off after detecting a blockage. After a certain period, the driver automatically attempts to restart the motor. If the rotor is still blocked, the protection is reactivated. If the obstacle has been removed, the motor starts normally and continues operation.

GH466 This is also a driver with locked rotor protection and automatic restart, but with a higher allowable output current of 600 mA, making the GH466 suitable for controlling higher-power motors or fans.

GH4212 This is a 24 V driver, making it suitable for 24 V fans, for example in industrial equipment, servers, or automotive applications. It features a full set of protections: thermal, reverse power connection, and locked rotor with automatic restart.

GH381 This is an integrated circuit containing a Hall sensor, commutation logic, and a transistor driver, designed for two-phase BLDC motors, such as cooling fans in computers and automotive applications that use two winding coils. The outputs are complementary—each winding receives signals in opposite phases, enabling effective and safe commutation. The GH381 is advantageous for larger, two-phase BLDC fans, providing more stable control, reduced vibrations, and improved cooling performance. It also includes a full set of protection features: thermal protection, locked rotor protection (LRP), and reverse power protection (RPP).

|

Symbol |

Package |

Application |

Operating voltage |

Current rating |

Hall sensor magnetic characteristics |

Operating temperature |

Protections |

|

TO94 |

Two-phase motors |

3~20V |

600mA |

Bop = 25GS Brp = -25GS |

-40~85°C |

Thermal, LRP, RPP |

|

|

TO94 |

Single-phase motors |

2.5~18V |

600mA |

Bop = 15GS Brp = -15GS |

-40~85°C |

Thermal, LRP |

|

|

TO94 |

Single-phase motors |

3~18V |

350mA |

Bop = 25GS Brp = -25GS |

-40~105°C |

Thermal, RPP |

|

|

TO94 |

Single-phase motors |

3~18V |

350mA |

Bop = 25GS Brp = -25GS |

-40~105°C |

Thermal, LRP, RPP |

|

|

TO94 |

Single-phase motors |

3~28V |

350mA |

Bop = 25GS Brp = -25GS |

-40~105°C |

Thermal, LRP, RPP |

Table 2. Summary of Motor Drivers with Built-in Hall Sensors by GoChip

Inductive sensor

The offering is complemented by the GC5505 device – a dedicated control IC for inductive proximity sensors. An external coil and capacitor are connected to the GC5505, forming an LC resonant circuit, which results in a complete inductive sensor. When a metal object appears nearby, the oscillation amplitude in the LC circuit changes, and the GC5505 detects this variation. The built-in circuits amplify and shape the signal, eliminating noise and distortion, after which the IC performs threshold detection – converting the inductive signal into a clear digital output that can be fed directly to a microcontroller or a motor control system.

The main features of the GC5505 include:

- Wide supply voltage range: 4.0–40 V

- Very low current consumption: < 0.7 mA – ideal for energy-efficient applications and long-term operation

- Integrated output stage: up to 70 mA – enables direct driving of loads

- High immunity to interference – stable operation in harsh environments (motors, industrial lines, automotive)

- Designed for 2-wire AC proximity sensors

- Temperature compensation – the IC compensates for changes in coil parameters at different temperatures, stabilizing the detection threshold

- Protection features: short-circuit, overload, and thermal protection – ensuring high reliability in industrial environments

- Operating temperature range: –25 to +85°C

Micros – an expert in Chinese semiconductor manufacturers

In addition to a broad portfolio of products from renowned global brands, Micros also stands out for its extensive experience in sourcing components from Chinese semiconductor manufacturers – both mainstream and highly specialized. We are currently observing a long-term trend: Chinese manufacturers are systematically increasing their significance in the global semiconductor market, offering increasingly technologically advanced components. Although this process is gradual and spread over time, all indications suggest that in many segments they will progressively displace well-known brands thanks to competitive pricing, shorter lead times, improving production quality and technical documentation, and greater flexibility in responding to market needs. A decade ago, their presence was largely limited to simple transistors or diodes; today, however, they increasingly supply advanced products that successfully replace components from brands such as ON Semiconductor, STMicroelectronics, Vishay, Diodes, Analog Devices, or Texas Instruments. An increasing number of electronics design companies are considering implementing Chinese alternatives instead of well-known Western brands, particularly where delivery time and cost pressure are critical.

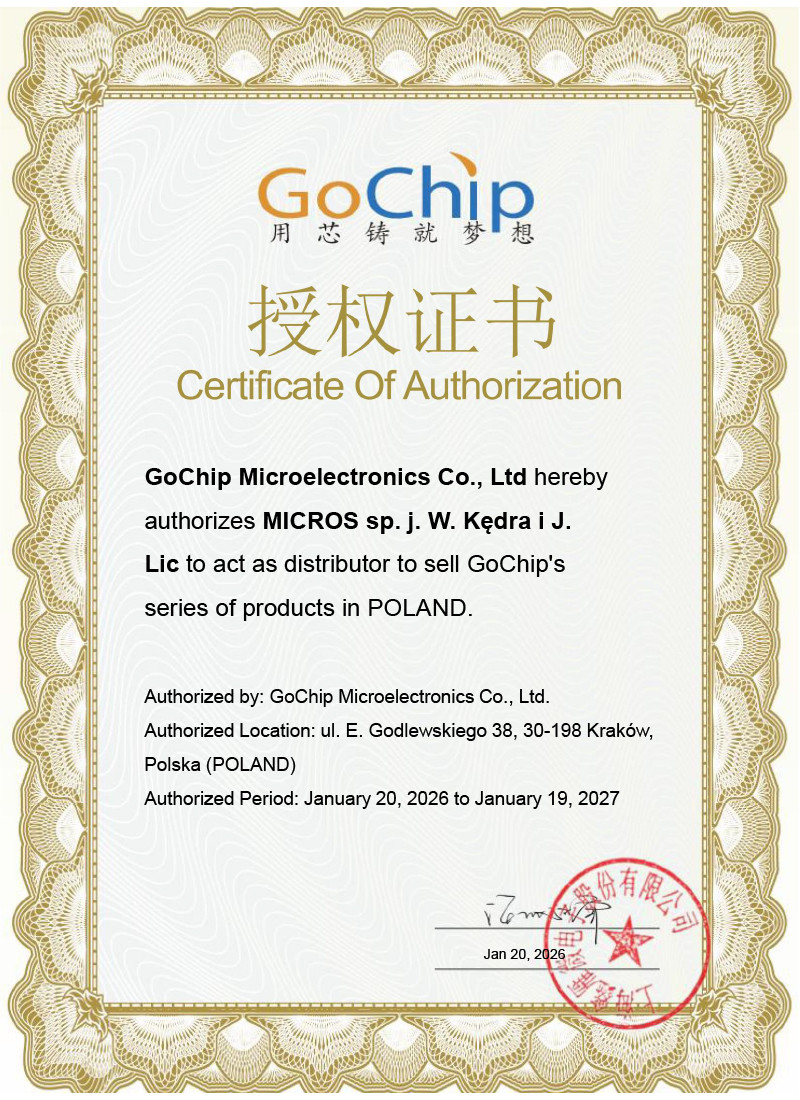

Micros is an authorized representative of GOCHIP, as confirmed by the manufacturer’s certificate.